As pallet racking systems are responsible for bearing heavy loads at varying heights, proper maintenance and inspections are essential to ensure the safety of everyone in the workplace.

As the majority of the damage that occurs with pallet racking happens through poor installation, overloading and forklift impacts, it's worth it to perform regular inspection of your selective pallet racking. So what should you look for before buying a Warehouse Racking system in Melbourne? Let’s find out:

Pallet Racking Inspection: What to Look For

When conducting an inspection of your pallet racking system, it's important to look for:

Signs of Tilt

Forklift damage can significantly affect your racking systems, especially misaligned systems. Misaligned or skewed racks are a severe workplace hazard and can act as a warning signal to a dangerous malfunction. Whether prompted by bad installation or tippy basements, always inspect your system for signs of tilt.

Signs of Corrosion or Rust

Rust can severely affect the integrity of your system. Inspect areas that display indications of any paint scrapes or discolouring, as rust weakens metal considerably.

Signs of Overloading

It's important to ensure you’re not overloading your racking system with too many goods. Take careful action to note the limits of your system and monitor their loads to ensure they are in-line with system limitations.

Signs of Damage

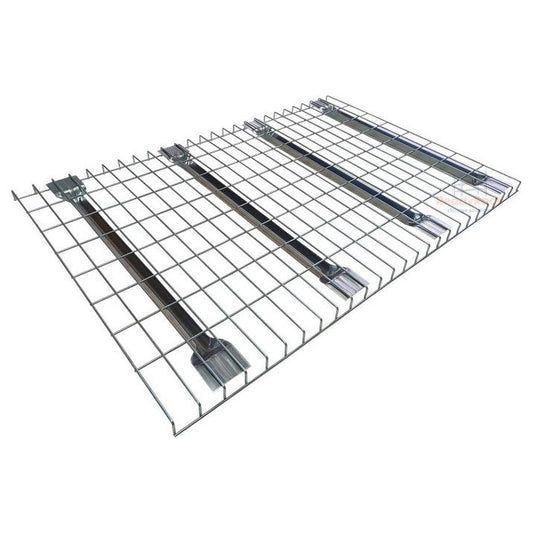

Generally prompted by forklift impact, bent or damaged beams can’t safely tolerate the same volume of the load as sound beams. Even the minor damages are a huge risk for mishaps & injury. The flat load beams can be damaged if you overload much in the same manner as the vertical beams. Give reasonable attention to beams that are scraped, bent, or otherwise malformed.

Connections

The connection of the beams to the upright needs meticulous inspections of all the parts concerned. All bolts, clips, safety pins and other beam connection accessories should be in position and unmanaged. Keep an eye for any broken scrapes, welds or any other informative indications of damage.

You certainly can expect several years of handy service from your pallet racking system once it’s checked regularly and meticulously for safety. Since professional inspectors know your local safety codes and standards, it’s worth contacting a professional for an inspection. Such simple and documented inspection may end up saving precious lives and your investment as well.

If you are looking for competent selective pallet racking installation or warehouse racking for sale in Melbourne then look no further than ReadyRack. Apart from manufacturing some of the highest quality pallet racking systems we also offer a comprehensive installation service at a pocket-friendly price. Call us today on 1300 307 229.